Magnetic Particle Inspection

MAGNETIC PARTICLE INSPECTION

- Materials Testing

- CHARPY IMPACT TESTING

- CHEMICAL ANALYSIS LAB

- FAILURE ANALYSIS LAB

- FASTENER TESTING

- HARDNESS AND MICRO-HARDNESS TESTING

- HEAT TREATMENT SUPPORT

- MAGNETIC PARTICLE INSPECTION

- MECHANICAL TESTING

- METALLURGICAL TESTING LAB

- MICROSTRUCTURE ANALYSIS

- POLYMER TESTING

- SALT FOG TESTING

- SEM/EDS LAB

- SURFACE FINISH CONSULTING

- TENSILE TESTING LAB

LET US EXCEED YOUR EXPECTATIONS FOR MAGNETIC PARTICLE INSPECTION.

Magnetic Particle Inspection (MPI) is a relatively low cost, yet highly effective non-destructive testing method used to identify surface and near-surface defects in ferrous metal parts or components, including castings, forgings, weldments and machined or stamped parts.

At QAI, we conduct fast and efficient wet magnetic particle inspection on a daily basis and employ a systematic approach in accordance with ASTM E1444 guidelines. This process begins before actual testing commences.

MPI PRE-TEST CHECKLIST

- Review provided part specifications and prints to determine if criteria can be met.

- Level II techs develop a technique that meets customer and test specification requirements for proper inspection.

- Technique is reviewed by a Level III inspector and revised/approved as needed.

- Once approved testing can commence.

Following approval of a technique that will meet the customer’s test specification requirements, our certified techs begin testing.

GENERAL 7-STEP INSPECTION PROCESS

- STEP 1 – Clean part as needed with a solvent degreaser so it’s free of oils and contaminants.

- STEP 2 – Secure part between head and tail stock of wet bench machine. Using a “head shot,” a pre-determined amount of electrical current is applied to magnetize the part according to the standard (ASTM E1444). Some test specifications call for multiple head shots.

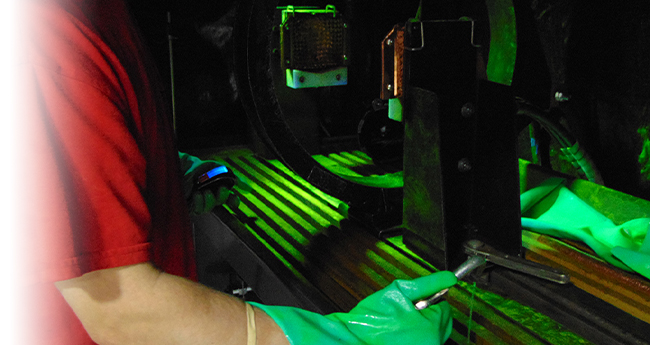

- STEP 3 – Bathe part in wet flourescent suspension solution that contains iron oxide particles, as an electric current is applied.

- STEP 4 – With the magnetic bench machine enclosed within a darkroom enclosure, UV light is applied to identify indications of any defects that appear in relation to the direction of the magnetic field applied to the part.

- STEP 5 – Depending upon the specific test requirements, one or more “coil shots” may also be applied to the part to identify any discontinuities that run in the opposing direction.

- STEP 6 – Demagnetize the part.

- STEP 7 – Following this thorough visual examination, the part is accepted or rejected, based upon pre-defined criteria. Failed parts are isolated from accepted parts and tagged accordingly.

Let QAI exceed your expectations for magnetic particle inspection. Our newly expanded MPI area is designed for optimum work flow with three Magnaflux benches operated by certified techs, thousands of square feet of available floor space to store incoming and outgoing parts, as well as an adjacent ground level dock for ease of access. In addition, as a full-service lab, QAI has expert metallurgists on staff available for consultation when issues arise. They can also perform additional testing, if necessary, to assess the severity or root cause of any detected indications.

Highlights

SPECIFIC TESTS AND/OR PROPERTIES MEASURED

METAL AND METALLIC COMPONENTS

TEST METHODS

• Magnetic Particle Inspection

APPLICABLE STANDARDS

ASTM E1444

KEY EQUIPMENT OR TECHNOLOGY

• Magnaflux Inspection Benches and Other Equipment

OTHER NON-DESTRUCTIVE TESTING

QAI also conducts:

• Liquid Dye Penetrant

• Real Time X-Ray

• Material Properties

For more information about our services please contact us at:

📞 USA 888.540.4024 📞 CANADA 877.461.8378

Founded in 1995 by a group of experienced certification and testing experts, QAI is an independent third-party testing, inspection and certification organization which serves the building industry, government and individuals with cost effective solutions through our global, in-house capabilities / services.

Latest News

-

Join QAI’s Impartiality Committee!

Be the Voice of Impartiality – Join QAI’s Impartiality Committee! Are you

19 December, 2024 -

2023 Alberta Edition of the National Building Code

Dear Valued Client, Subject: Announcing the publication of the 2023 Alberta Edition

5 April, 2024 -

QAI LABORATORIES (QAI) AND ATRONA TEST LABS (ATL) JOIN FORCES TO EXPAND TESTING CAPABILITY

QAI Laboratories is pleased to announce the acquisition of ATRONA Test Labs,

18 March, 2024

Services

Contact

USA 1(888)540.4024

USA 1(888)540.4024

Canada 1(877)461.8378

Canada 1(877)461.8378

Europe info@qai.org

Europe info@qai.org

China china-info@qai.org

China china-info@qai.org

S Korea asia-info@qai.org

S Korea asia-info@qai.org