Microstructure Analysis

MICROSTRUCTURE ANALYSIS

- Materials Testing

- CHARPY IMPACT TESTING

- CHEMICAL ANALYSIS LAB

- FAILURE ANALYSIS LAB

- FASTENER TESTING

- HARDNESS AND MICRO-HARDNESS TESTING

- HEAT TREATMENT SUPPORT

- MAGNETIC PARTICLE INSPECTION

- MECHANICAL TESTING

- METALLURGICAL TESTING LAB

- MICROSTRUCTURE ANALYSIS

- POLYMER TESTING

- SALT FOG TESTING

- SEM/EDS LAB

- SURFACE FINISH CONSULTING

- TENSILE TESTING LAB

WORLD CLASS METAL TESTING AND ANALYSIS IN THE HEART OF THE MIDWEST.

At QAI, we offer you one of the most advanced metallurgical test labs in the country with the latest instruments, equipment and technology, and full time experts on staff. Our metallurgical lab has four fully-equipped Metallographs with full image analysis capabilities utilized for microstructure examination, a Keyence VHX-5000 Digital Microscope, two full Scanning Electron Microscopy (SEM) and Energy Dispersive X-Ray Spectroscopy (EDS) systems with full digital imaging, two fully-automatic micro-hardness testing systems capable of performing all sorts of routines and mapping procedures, and the ability to perform simultaneous testing on up to eight samples, automated direct hardness testers, and much more.

ADVANCED EQUIPMENT AND CAPABILITIES

At QAI, we’re microstructure evaluation experts. Utilizing a range of proprietary methods and techniques, along with state-of-the art lab software and equipment, including a new Keyence VHX-5000 Digital Microscope, we’ve taken microstructure evaluation and analysis to a new level. Our new next-generation microscope has a large depth-of-field and advanced measurement capabilities for inspection of metallurgical or other specimens, as well as failure analysis. It lets us observe any area of the sample completely in focus with real-time depth perception and 3D high resolution HDR imaging capability; so, we can analyze the topography or view it from any angle with magnification up 5000x. These images can then be captured and saved, and/or measured directly on the screen. This device also utilizes advanced image stitching technology which gives us an overall view of the target at high resolution (up to 20,000 by 20,000 pixels) in real time.

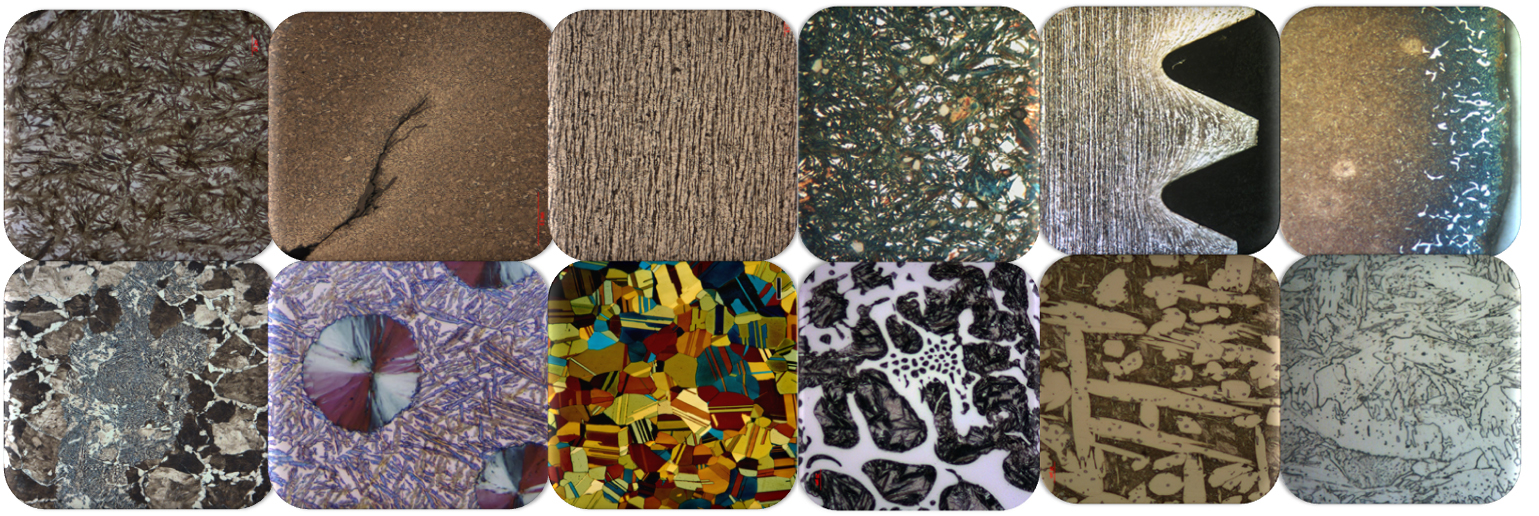

Pictured above: Photomicrographs taken at QAI of various microstructures of ferrous and non-ferrous metals.

Our metallurgical lab also has four fully-equipped Metallographs with full image analysis capabilities utilized for microstructure examination. For steel mills, fabricators, machine shops, and other high-volume clients, our automatic stage microscopy and image analysis enable us to accurately analyze up to eight specimens simultaneously – saving you both time and money. So, if you are looking for grain size, banding classification, simple phase analysis, or raw material cleanliness (inclusion ratings), call us for a quote.

Grain size measurement can be part of a more extensive microstructure examination or it can be conducted by itself as an inspection tool after a forging operation, a heat treat operation, a rolling operation, etc. Typically, the finer the grain size the better the material condition. Most alloy steels require ASTM 5 or finer grain size and some tool steels require 10 or finer grain size.

In addition, we can also determine grain boundaries, nodularity, phase percent, particle size, dimensional measurements, coating thickness, retained austenite rating, morphology, cast iron graphite analysis, spheroidization analysis, rolling direction, carbides analysis and distribution, ETA phase analysis, surface condition and grinding effect, microporosity analysis, percent phase (pearlite, ferrite, bainite, martensite, etc.), cementite, steadite, carbides in any material, tempered or untempered martensite, as well as non-ferrous materials. We also perform microstructure analysis on stainless steels of all grades including corrosion-resistant steels, heat-resistant steels, magnetic and non-magnetic, and high-strength stainless steels. And all at some of the most competitive prices in the industry.

Highlights

SPECIFIC TESTS AND/OR PROPERTIES MEASURED

• METALS AND METALLIC COMPONENTS

• DUCTILE IRON AND DUCTILE IRON COMPONENTS

TEST METHODS

Metallographic Evaluation:

• Sample Preparation

• Macroetch / Microetch

• Inclusion Rating

• Intergranular Corrosion

• Average Grain Size

• Nodularity and Nodule Count

• Photomicrography

• Light Microscopy

• Case Depth

• Image Analysis

APPLICABLE STANDARDS

ASTM E3, E340, E381, E407, E45 (Method A), A262 (Practice A and E), E883 SAEJ423, E1382, E112, E2567

KEY EQUIPMENT OR TECHNOLOGY

• Microscopes with Automatic Stages

• Image Characterization and Automatic Microhardness Testers with Mapping

• Image Analysis Microscopes and Software

For more information about our services please contact us at:

📞 USA 888.540.4024 📞 CANADA 877.461.8378

Founded in 1995 by a group of experienced certification and testing experts, QAI is an independent third-party testing, inspection and certification organization which serves the building industry, government and individuals with cost effective solutions through our global, in-house capabilities / services.

Latest News

-

Join QAI’s Impartiality Committee!

Be the Voice of Impartiality – Join QAI’s Impartiality Committee! Are you

19 December, 2024 -

2023 Alberta Edition of the National Building Code

Dear Valued Client, Subject: Announcing the publication of the 2023 Alberta Edition

5 April, 2024 -

QAI LABORATORIES (QAI) AND ATRONA TEST LABS (ATL) JOIN FORCES TO EXPAND TESTING CAPABILITY

QAI Laboratories is pleased to announce the acquisition of ATRONA Test Labs,

18 March, 2024

Services

Contact

USA 1(888)540.4024

USA 1(888)540.4024

Canada 1(877)461.8378

Canada 1(877)461.8378

Europe info@qai.org

Europe info@qai.org

China china-info@qai.org

China china-info@qai.org

S Korea asia-info@qai.org

S Korea asia-info@qai.org