QAI Laboratories is an established, independent test and assessment agency offering evaluation of Machinery to worldwide requirements.

In-Situ Services, at your facility anywhere in the world include:

- Electromagnetic Compatibility Testing and Performance Evaluation

- Machinery Directive Compliance Assessments, Testing, Risk Assessment and Technical File Preparation

- Pressure Systems Compliance Assessment and Notified Body Interface

- ATEX Directive Compliance Assessment and Notified Body Interface

- EU Directive Consultancy, Technical File Preparation, and EMC Filters

Laboratory Services offered include:

- Electromagnetic Compatibility Testing & Performance Evaluation

- Low Voltage Directive Evaluation & Safety Evaluation

- Temperature, Humidity, and Environmental Testing

- CE Marking Assistance

The QAI team of compliance engineers have many years of experience in industrial and commercial test methodologies and standards. Continued involvement in IEC and ISO standards development keeps QAI current in safety standards requirements. Our engineers have been associated with European standards committees for many years giving us an in-depth understanding of the European Union and what it takes to have your product comply with the requirements.

Machinery Safety

EMC Testing (In-situ or in our labs)

Electrical Safety Testing

Environment Testing

Services

Machinery Safety Evaluation

Manufacturers exporting machinery to the European Union must fulfill the Essential Health and Safety Requirements of the Machinery Directive (2006/42/EEC). This includes the need for a comprehensive risk assessment evaluation according to EN ISO 14121-1, guidance on the requirements of safety related control functions (EN ISO 13489-1) and the development of the required Technical File. As a member of IEC Technical Committee 44, QAI participates in the maintenance of IEC 60204-1 and IEC 62046 safety standards.

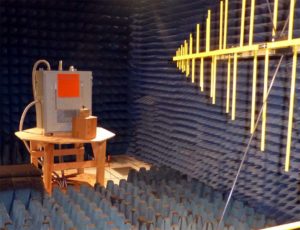

EMC Laboratory Testing

It is never too early to assess a product design for EMC performance. Access to an accurate and rapid assessment facility can expedite your product to market. QAI is able to assist manufacturers and designers through all stages of product development. Experienced engineers are available to assist in solving difficult EMC issues. Products and machinery which realistically cannot be assessed in the typical EMC laboratory may be evaluated in-situ. QAI has extensive expertise in conducting in-situ assessments for a wide range of different and diverse equipment. Working in this environment requires flexibility, patience and innovation. QAI has an affiliation with a Notified Body in the EU and UK who specializes in the on-site assessment of machinery and can issue statements of compliance based on QAI’s EMC testing.

Electrical Safety Testing – Machinery

Electrical Safety assessment and test are a world-wide requirement. Ensuring that your product is safe to use and operate is vitally important in today’s world of product liability. QAI has the expertise and is equipped to evaluate products to specific safety standards both at your facility, in the field, or at our laboratory. QAI is a OSHA recognized NRTL, Standards Council of Canada accredited certification body, and accredited field evaluation body for electrical safety. For more information about QAI’s electrical safety capabilities, please visit: https://qai.org/electrical/

Regulatory Compliance

QAI’s team of experienced engineers are on hand to advise and assist manufacturers in the development and implementation of a compliance strategy. The strength of QAI is firmly invested in its employees. We are able to work with you to determine the requirements applicable to your machine and create a scope of work to obtain the necessary approvals.

CE Marking

Products which fall within the scope of European Union New Approach Directives require mandatory CE Marking. The correct application of all applicable Directives may involve third party testing, system assessment, and technical file preparation. Manufacturers must be aware of the product liability issues of the European marketplace. QAI is able to develop a compliance program for your product including all documentation, testing, and file preparation. Experienced engineers assist you in the fulfillment of these requirements.

Environment Testing

Extremes of temperature and humidity, dust, and vibration are the leading causes of product failure. Verification of the design to product specification parameters is essential to good product performance and life. QAI is equipped to conduct extreme temperature and humidity testing, dust, corrosion, vibration & shock testing. Our experienced team will work with you to develop a reasonable environment profile for your product.

Product Filters

QAI is a distributor for the vast range of Deltron-Emcon / Roxburgh EMI Filters and suppression components for electronic assemblies and industrial machines. Recognized as the United Kingdom’s largest manufacturer of RFI filters, Deltron-Emcon filters and components are available to you from inventory. QAI’s expertise in conducted emission and immunity give you the best solution for filter application.

Inclusion of an AC mains filter in a design is an important part in the overall EMC strategy for a product or system. To reduce the conducted emissions along the AC mains cable, the correct installation of an RFI Filter (or EMI Filter) is critical if the full potential is to be realized. Protecting a product or system from unwanted transients and surges has become another vital part of EMC strategy. Transients and surges may cause irregular operation and in some cases permanent component damage. Correct installation of transient and surge suppression can protect from expensive damage.

For more information about electrical safety testing and certification services please contact us at:

📞 USA 888.540.4024 📞 CANADA 877.461.8378

USA

USA  Canada

Canada  Europe

Europe  China

China  S Korea

S Korea